Having a good set of wrenches is a staple of any mechanic or handyman’s tool assortment. They are used to drive or remove hex head screws, nuts, and bolts from their location. There are a lot of tools that you can get away with not having, but a set of wrenches, usually several, does not fall into that category. When you start a new project, having the right tools at the beginning can make all the difference, but each tool has its own specific purpose. So how do you know which wrenches you will need? You will get your answers here!

Socket wrenches are a type of wrench that fits snugly around the fastener, usually a nut or bolt. This is one of the most well-known and commonly possessed toolsets. It helps you quickly drive or remove a hex head fastener by using a one-way mechanism called a ratchet. This mechanism can be reversed to allow fast movement in the opposite direction. This allows you to keep turning the fastener without removing and repositioning the wrench each time.

There are other types of non-ratcheting wrenches, however, and they can be useful in many situations where a larger socket driver falls short. Like the ratcheting wrenches, the non-ratcheting sockets have a recessed cavity that fits tightly around the fastener. This allows the fastener to be turned on most, if not all, sides at once. The drawback to non-ratcheting socket wrenches is that they will need to be removed and repositioned after each turn. The compromise to this is that they can frequently fit in areas that ratcheting wrenches cannot. Another benefit is the absence of the ratcheting mechanism, which can break under hard use.

Both ratcheting and non-ratcheting socket wrenches can be found in metric as well as standard. Depending on the set you choose, you may have popular sizes, or you may have a wide range of both sizes. There are also an extremely large variety of handle shapes, sizes, and materials, along with different physical designs of the wrenches themselves.

Types Of Ratcheting And Non-Ratcheting Socket Wrenches

a) Ratcheting Socket Wrenches

Ratcheting socket wrenches come in several different styles and functions, some with fixed sockets and some with interchangeable. While ratcheting sockets are nearly always interchangeable, some are not. Fixed socket wrenches can be separated similarly, though they are more often non-ratcheting, with the exceptions being few and far between. Some types of fixed socket wrenches include:

a.1) Lug Wrench

Usually seen as the four-way tire iron, the lug wrench is fixed to provide the strength and rigidity needed to break lug nuts free of the wheel studs. They are often X or L shaped, and will occasionally have a small pry tip to remove a hubcap or other cover.

a.2) Nut Driver

This non-ratcheting socket wrench resembles a screwdriver, often with a plastic or composite handle, and a four to an eight inch shaft with a set size socket on the end. They are most frequently used to drive or remove a nut onto a fixed stud. They can also be used to hold a nut stationary while the fastener married to it is removed. Nut drivers are available in metric and standard, and often will have options for length as well. Sets can be impractical if you have space constraints.

a.3) Saltus Wrench or Flex-Head Socket

These are an oddly useful mixture of an open-end wrench on one end, and a socket of the same size, often hinged, on the other end. These are amazing tools to keep a variety of useful sizes. Excellent for working in small spaces where you may not be able to work the socket onto the fastener. Alternately useful for starting a tough bolt, then finishing it quicker with the other side.

a.4) T-Handle/Spark Plug Wrench

These are not generally very common, aside from spark plug wrenches for small power equipment. It is often just a simple metal tube with hex sockets on either end, and a couple of holes drilled for a removable bar to create a simple handle. If you have outdoor power equipment with spark plugs, this is a great wrench to keep around, since it gives deep reach to the cylinder head, and the T top makes one-handed wrenching easy and fast. A bonus with these is you will often only need one or possibly two sizes since spark plugs are a standard size depending on the application.

a.5) Breaker Bar

This is an extension bar that attaches to your current socket handle, and in some cases can be used by itself. It adds length, and therefore leverage to stubborn nuts and bolts. They are frequently made much heavier and more sturdily than standard socket wrenches, and will usually have a swivel head.

They are used due to their added length to multiply the force the user can exert, in order to break free stuck nuts and bolts. Since a breaker bar can often destroy the ratchet mechanism of a standard ratcheting socket wrench, it is generally found only in a fixed head style. They are frequently able to utilize standard drive sized sockets.

a.6) Spinner Handle

These are very similar to a nut driver, but they are an interchangeable socket version. They consist of a standard screwdriver style plastic handle, with a metal shaft. At the end of that shaft will be a male drive end, frequently only up to half-inch drive. That drive will accept any matching size sockets of metric or standard sizing. The spinner handle provides a quick way to loosen or tighten nuts and bolts that may not need as much muscle as in other applications. Particularly in small benchtop assembly or repair jobs, the spinner handle is extremely quick in driving and removing nuts and bolts, while avoiding using a full-sized socket wrench.

Related Reads: Best Tool Backpack for Mechanic!

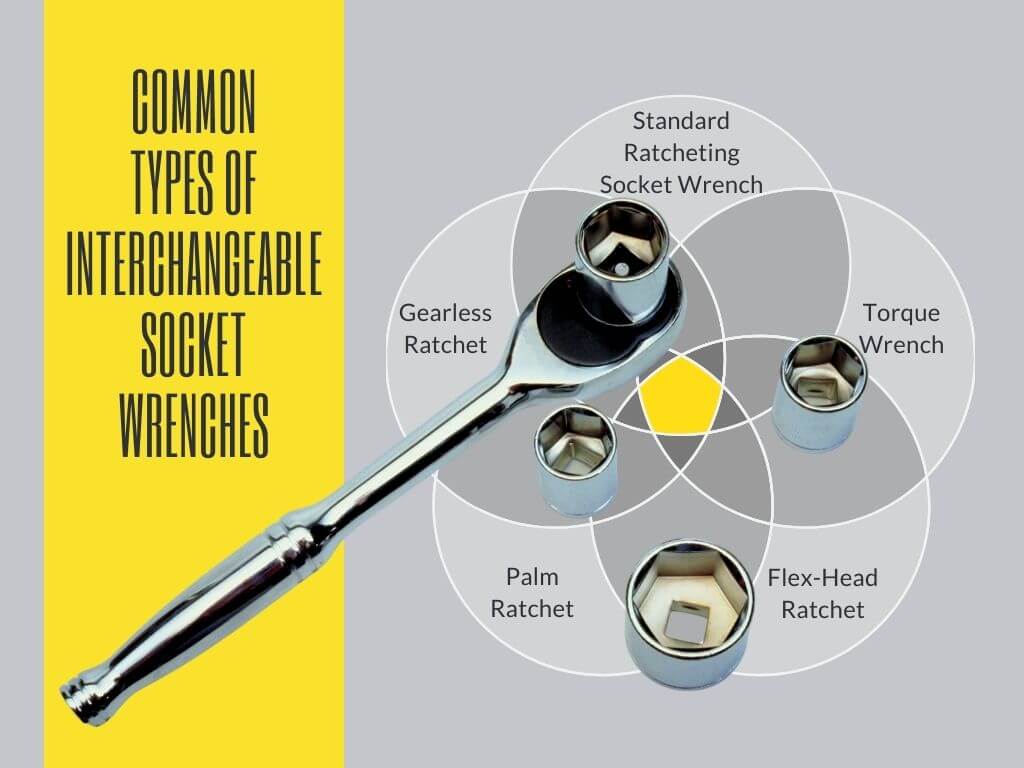

b) Some common types of interchangeable socket wrenches will include:

b.1) Standard Ratcheting Socket Wrench

These are by far the most common type of socket wrench. They have a ratcheting mechanism inside the head that will allow a nut or bolt to be loosened or tightened with a reciprocating motion. This lets the user keep the wrench seated on the fastener, rather than removing and resetting it after each turn. They can be used to tighten or loosen by flipping a small switch or lever on the head, allowing motion in only one direction.

Frequently the wrench will be sold with an entire set of sockets that will match its drive fitting. Socket wrenches are with drive sizes in quarter-inch increments that start at a household-use quarter-inch, and run all the way up to a massive three-quarter drive and even larger on industrial applications.

The advantage of these wrenches is their versatility and speed. Since the size of the socket can often be changed in just seconds, they can be quickly adapted to nearly any need in the workshop, at the job site, or at home. Some are even geared toward tight spaces, having greater tooth numbers, so that more movement is gained with more limited movement giving smaller strokes.

b.2) Torque Wrench

A torque wrench is very similar to a standard ratcheting socket wrench, but it only allows a predetermined amount of torque to be applied to the fastener. These are most likely to be found in an auto shop, or similar. They are used when you must tighten a nut or bolt to a particular specification, to prevent either over or under-tightening of the fastener.

In their most common form, they have a dial on the ratchet head that allows a foot-pound torque setting to be designated. Once this force is reached, the wrench clicks and cannot tighten any further. Sometimes, to reach higher values, torque multiplying devices like a breaker bar are used to ensure the torque requirement is met.

b.3) Flex-Head Ratchet

These are also very similar to a standard ratcheting socket wrench, but they differ in that their head is hinged. This allows the head to pivot or swivels into the position that is most useful for the user. These are another great wrench to have a least one of since it will work with all your regular sockets. The bonus is they provide a degree of movement and flexibility you can’t get from a standard.

b.4) Palm Ratchet

These are great for tightening, loosening, or holding a nut still. They are a palm-sized round handle with a knurled edge for grip. They are often found in both quarter drive and three-eights drive, so they can easily take your current sockets.

b.5) Gearless Ratchet

These are fairly expensive but impressive ratchet drivers. They do not use a conventional gear and catch design, they utilize bearings instead. This gives them a nearly infinitely small arc swing and has a virtually silent operation. One of the trademark sounds of a ratchet is the click-click of the backswing arc and this eliminates that. If you find yourself in a situation where even a fine-tooth ratchet is not moving things along as quickly as you’d like, the gearless ratchet may just be your dream tool. No matter what sort of range of movement you are able to get a gearless ratchet should show improvement over everything else.

Applications Of Ratcheting And Non-Ratcheting Socket Wrenches

Ratcheting Socket Wrenches

Generally ratcheting socket wrenches are commonly used when there are space limitations and longer bolts or studs for nuts that will require more overall turns to tighten or loosen. The ratcheting motion allows a huge amount of time to be saved by not having to remove and replace the tool on the fastener after each turn.

Ratcheting socket wrenches are the beloved favorite of every neighborhood mechanic and tinkerer. They are nearly universal in their versatility and are so common that entire sets can be obtained for the kitchen tool drawer for only a few dollars in some cases.

Non-Ratcheting Socket Wrenches

Non-ratcheting socket wrenches are most frequently used when movement is not a concern, but the force is. With the absence of the ratcheting mechanism, the non-ratcheting wrenches can be much more robust. This allows them to be used in situations like lug wrenches and breaker bars, where you have plenty of room to move around, but you need to break a nut or bolt free.

Shops that work on larger vehicles, machinery, and so on will often have larger wrenches like these that do not ratchet. Also, shops that work on older or more frequently neglected equipment may have them on hand as well, to help free rusted and otherwise corroded fasteners.

Smaller non-ratcheting socket wrenches are frequently seen in the tool kits of those who work on small machines, appliances, or small engines. The most popular form of non-ratcheting wrenches in these situations are arrays of nut drivers and spinner handles for tiny nuts and bolts. There are even sockets for digital devices, which have head sizes of fractions of millimeters. Those who service smartphones, tablets, and other similar devices, are often seen with entire sets of nut drivers that can fit in a case the size of a deck of cards.

Wrapping Up

There is such an overlap in usefulness and functionality in socket wrenches and ratcheting socket wrenches, that often choosing one for your needs can be a bit overwhelming. But, by following this breakdown, and aligning it with your own needs, you should be able to decide which style is right for you.