Before going through the types of blades you can use to cut pressure-treated wood, you must understand what it is.

Pressure-treated lumber has chemicals driven into it to make it more durable and less likely to get damaged by water, mold, or insect infestation.

This type of lumber can also be used as a fire retardant.

Since this is a special type of wood, you’ll need a special blade to cut it.

Read the article to know about the best circular saw blade for pressure-treated wood.

Short on time? Check out Comparison Table!

Let’s glance at this comparison table to have some necessary product information of the top 3 Circular Saw Blade before diving into each blade’s detailed information.

Table could not be displayed.

- Best Circular Saw Blade For Pressure Treated Wood On The Market

- Do I need a special blade to cut pressure-treated wood?

- What type of blade is best for cutting pressure-treated wood?

- Which one is better: portable or corded circular saws?

- What are the benefits of using a circular saw blade for pressure-treated wood?

- How do you choose a good circular saw blade for pressure-treated wood?

- Top 3 Circular Saw Blades Reviews

- People Also Ask About Circular Saw Blade

- Final Words

Best Circular Saw Blade For Pressure Treated Wood On The Market

To save time, I have made a list of 3 top circular saw blades along with explicit purposes. You might need to take a look at the following list, which has been tested multiple times.

Do I need a special blade to cut pressure-treated wood?

Yes, you will need a blade with certain features to safely cut pressure-treated wood. Since this sort of wood has a lot of fibers and can hold moisture, it can be challenging to cut it. The right type of blade should not frequently slip as slipping can cause the wood to chip and splinter.

What type of blade is best for cutting pressure-treated wood?

Circular saw blades are best for cutting pressure-treated wood. They are more powerful than other blades and provide smooth results. They are also designed to resist corrosion, which is an essential feature for cutting pressure-treated wood. They are powerful and manufactured specifically for best results.

Which one is better: portable or corded circular saws?

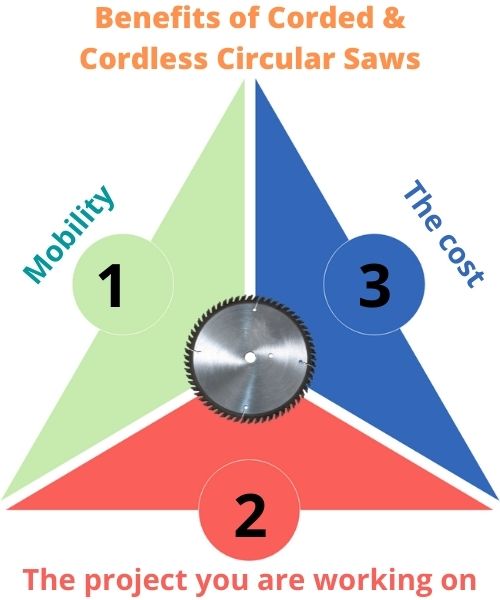

To choose between corded and cordless circular saws, we first need to see the differences and the benefits they have to offer.

Mobility

If you are working in different areas, including those without a power connection, you need to be able to move around freely. This is why a cordless or portable circular saw will serve you better.

Portable saws won’t get in your way and will allow you to work in various regions even when the power supply seems to be a problem in certain areas. These are best suited for outdoor projects.

Corded circular saws, on the other hand, don’t do well on this part. The power cords they have to offer are a minimum of 3 meters long. You can find a range of long cords, but they still don’t have the same benefits as cordless circular saws.

You’ll only be able to work within a limited reach. Don’t forget that you’ll also need to have a power connection to use these saws. They do work better in specific ways. They have more power, and they’ll get your work done much faster because there’s a direct power supply.

The project you are working on

The next factor you have to consider is the power and mobility your project requires. If your project is large and it needs a good amount of power supply, then a corded circular saw is the way to go. Corded saws can provide a continuous power supply, so you won’t have to use rechargeable batteries here. They also come with larger blades as opposed to cordless saws. That contributes to the power these saws have.

You can use them from both your left and right hands. Plus, they are versatile in terms of the materials they can work with. You can use them on wood, aluminum, plastic, and metals. These factors make them ideal for large projects.

Cordless circular saws don’t have the same advantages. They aren’t made for large projects because there isn’t a power supply to keep them going for long hours. There run on rechargeable batteries that last for about 4-5 hours when you use them continuously. Also, keep in mind that as the battery drains, it affects the performance of the saw. That means it’ll start working slower eventually as it runs out of power. At the same time, they are lightweight, quiet, and safer than corded circular saws.

So, you need to keep your work in mind when you’re purchasing a circular saw as your project determines what you settle on.

The cost

Corded saws are much more expensive than cordless ones. It is because they are used for large projects requiring high amounts of power. Their cords can also get damaged from cuts or breaks. In case that happens, you’ll have to pay extra to get them repaired.

Cordless saws are better in terms of cost because, aside from being cheaper, they come with kits you can utilize to work on a variety of projects.

Which one is better?

Both of them will work fantastic depending on what you want to do. However, corded saws can be better for newbies. That’s because you can use them at home where there’s a power supply. Suppose you are working from different areas and have some experience working with these tools. In that case, you should definitely get a cordless circular saw.

What are the benefits of using a circular saw blade for pressure-treated wood?

They are versatile

Circular saw blades offer versatility in terms of shape when you’re cutting pressure-treated wood. They can cut through the wood and leave complicated cuts with excellent results. You can make various cuts, including finish cuts, plunge cuts, cross cuts, and many more. The best thing is that you don’t have to change the blade when cutting. A single blade is more than enough to give all these different cuts.

You can even adjust the depth and angle of your blade with these saws. Depending on your project, you can make the changes you prefer. The blade should get set with ease, allowing you to have better control over the finished product. Most circular saws have thin-kerf blades that also contribute to making the blade more versatile.

They come with additional features

Circular saw blades have some fantastic additional features to help you with your project. They come with LED lights that can help you cut your pressure-treated wood with precision. These are especially useful in conditions where you don’t have enough light.

Some companies make models with dust collection ports and collection bags that are detachable to allow you to clean out the dust. Cleaning out the dust gives you a clear cutline to help you cut your pressure-treated wood with ease.

You can use left or right-handed circular saws

Circular saws are available for both left and right-handed users. This makes it easy for you to use it. Pressure-treated wood can be difficult to cut, but with circular saws, you can cut it with ease by holding it whichever way you prefer.

Remember that most left-handed circular saws are cordless, while you’ll find right-handed circular saws attached to power cords.

Left-handed circular saws have the motor on the right and the blade on the left side. This arrangement is advantageous as you can hold the primary handle with your left hand and the latter with your right hand.

Unlike right-handed circular saws, these give you a clear view so that you don’t end up harming yourself. These are great for right-handed users, especially when working with a rigid material such as pressure-treated wood.

On the other hand, right-handed circular saws have the motor on the left and the blade on the right side of the saw. You hold the primary handle using your right hand and the latter handle with your left hand.

They are powerful and durable

Unlike other available options, circular saws are significantly powerful. Their blades are designed to give easy cuts and keep you safe simultaneously. Some models even have safety buttons that can cause the blade to come to a halt in an emergency. They are also very durable, which is vital for pressure-treated wood as it can harm other types of blades.

Pressure-treated lumber is corrosive, which is why you need a durable blade with a protective coating. That’ll keep the blade sharp and running for an extended period. It can also reduce the kickback you can face while cutting the wood.

How do you choose a good circular saw blade for pressure-treated wood?

If you are using circular saws, you need a durable blade with carbide teeth, vast space between each tooth (also known as deep gullets), and a coating that’ll allow the wood to not stick to the kerf and protect the metal of the blade from corrosion. These features will prevent the blade from clogging up, which is ideal for getting neat, even results.

It’s also better to have kerf with alternating carbide tips since they offer different angles to tear through the wood. You can use them to achieve a neat finish. They are primarily designed to make cross-cuts, but they’ll word amazing with whatever type of cut you want to make on your pressure-treated wood.

Top 3 Circular Saw Blades Reviews

This part helps you with an intensive knowledge of circular blade features, pros, and cons to get you to the accurate decision at the end. Let’s find out more of Circular Saw Blade for Pressure Treated Wood:

1. Freud D0740A Diablo 7-1/4 40 Tooth ATB Finishing Saw Blade

This Freud D0740A Diablo saw blade has a clean-cutting design, which offers a smooth performance. The thin kerf between every blade is about 0.59-inch wide with a hook angle of 15 degrees. These kerfs are laser cut to give you more control over the pressure-treated wood. On top of that, it has 40 ATB (alternate top bevel) teeth. ATB means that the blades are of two kinds; more specifically, they’re the mirror images of each other.

The top of the blades is ground at an angle to give smooth cross-cuts. These will help you achieve the most accurate cuts efficiently.

What I love the most about this blade are the laser-cut stabilizer vents. They reduce noise and vibration while you’re working, giving your hands more control while keeping them relaxed at the same time. It also helps in minimizing friction and prevents the blades from warping.

It has laser-cut heat expansion slots to let the blade expand safely when the heat builds up. This keeps the cut straight and neat. The durable micro-grain titanium carbide is highly durable and ideal for pressure-treated wood.

I am also impressed by the shock-resistant brazing that helps the carbide tips to go through severe impact. The Perma-Sheild non-stick coating on the blade makes it heat resistant and less likely to corrode. These features help in extending the life of your circular saw blade.

The only con this blade has is that while it works great for most types of wood, it can sometimes have difficulty making smooth cuts in plywood. Other than that, this is one of the best carbide circular saw blades, and it works fantastic.

2. DEWALT 7-1/4″ Circular Saw Blade for Pressure Treated and Wet Lumber

This Dewalt 7-¼” circular saw blade for pressure treated and wet lumber has tough Tungsten Carbide for maximum durability. This will also ensure that the blade stays sharp for a long time. Friction from the surface of pressure-treated wood can sometimes get in the way of you, creating neat cuts. That is why this blade has a specially designed anti-stick coating that reduces friction and gum-up.

The ribbed heat vents help the blade run at a lower temperature, preventing the potential damage that can be caused due to heat build-up. This, in turn, reduces blade bending and flexing. The manufacturer designed a thin kerf, making the blade versatile, leading to smoother and faster cuts. This makes it the best circular saw blade for pressure-treated lumber.

The DEWALT circular saw blade is one of the best blades you can find in the market. It cuts through pressure-treated wood and wet lumber like butter. It makes precise cuts without leaving any jagged areas. The con here is that this is a slightly expensive option, but still, it’s a great choice when it comes to pressure-treated wood.

3. Makita B-61656 7-1/4″ 24T Carbide-Tipped Max Efficiency Circular Saw Blade

The Makita 7-¼ inches carbide-tipped farming saw blade is ideal for numerous projects featuring pressure-treated wood. The Ultra-thin kerf design (0.057 inches) allows you to make all types of cuts. The wide range of cuts gives you more control leading to a better result.

The blade teeth are specially engineered to reduce the damage that comes with the load put on this tool. This blade is designed to have a reduced swing width that leads to smooth cuts and increased ease in cutting. The alternate blade tips enhance its performance.

If you compare this to other blades, Makita B-61656 saw blade gives up to 70% faster-cutting speed and up to 70% more cuts with every charge. This blade is best suited for milter cuts, rip cuts, and cross-cuts on your pressure-treated wood.

Talking about comparison, this blade is cheaper than most other blades and is one of the best blades for cutting wood.

The high-grade tungsten carbide tips make the blade durable and ideal for use in many environments. It’s resistant to corrosion, making it a great material to cut pressure-treated wood. It has a longer blade life due to low thermal expansion. The blade also has alternate top alternate face(AFATR) with racer carbide tips that provide easy cuts. The manufacturer included a protective coating on the blade to reduce pitch build-up.

The drawback of this blade is that it doesn’t work well on certain types of wood, leading to some kickback. It’s also ineffective against the wood with nails embedded inside.

People Also Ask About Circular Saw Blade

Is pressure-treated wood harder to cut?

Yes. When the wood is treated, chemicals are driven into it, replacing the air inside. It can make the wood bulkier than untreated wood, and it can be harder to cut. However, you can think of this as wet wood. You will need a blade with more kerf because that is less likely to jam in the cut.

What is the best blade to use for cutting across the grain of the wood?

Since cross-cuts require you to cut through the wood fibers, you need a blade with smaller teeth than those in a ripping blade. However, you need to have more of them. Some cross-cutting blades are designed to be smaller on purpose to have a fast-cutting rate, leading to smoother cuts. Alternate-top bevel teeth are ideal for making cross-cuts as the tips are designed to be on opposite angles.

Can I rip pressure-treated wood?

Yes, pressure-treated wood is easy to rip. You need the right kind of blade with a thin kerf for minimum kerf loss.

Final Words

All in all, pressure-treated wood can seem difficult to work with, but with the right type of blade, it’ll become a piece of cake. Circular saws are ideal for cutting this type of wood. You can choose between portable and corded circular saws as both of them have their benefits.

The best circular saw blade for pressure-treated wood would include a thin kerf blade and alternate-top bevel carbide tips. The blade should also be made of a durable material that’ll prevent kickback. You should opt for one of the three products I mentioned in the article.